Process Mining at Samsung Electro-Mechanics

discovery performance-analysis promBy BPI Lab UNIST

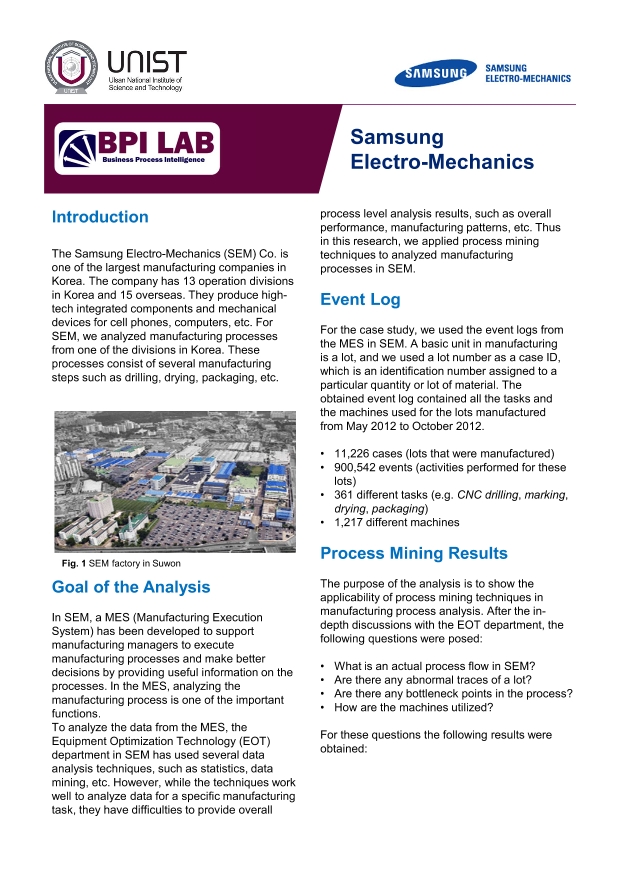

The Samsung Electro-Mechanics (SEM) Co. is one of the largest manufacturing companies in Korea. The company has 13 operation divisions in Korea and 15 overseas. They produce hightech integrated components and mechanical devices for cell phones, computers, etc. For SEM, we analyzed manufacturing processes from one of the divisions in Korea. These processes consist of several manufacturing steps such as drilling, drying, packaging, etc.

In SEM, a MES (Manufacturing Execution System) has been developed to support manufacturing managers to execute manufacturing processes and make better decisions by providing useful information on the processes. In the MES, analyzing the manufacturing process is one of the important functions.

To analyze the data from the MES, the Equipment Optimization Technology (EOT) department in SEM has used several data analysis techniques, such as statistics, data mining, etc. However, while the techniques work well to analyze data for a specific manufacturing task, they have difficulties to provide overall process level analysis results, such as overall performance, manufacturing patterns, etc. Thus in this research, we applied process mining techniques to analyzed manufacturing processes in SEM.

Case study details

- Organization:

- Samsung

- Case study year:

- 2014

- Country:

- South Korea

- Latest update:

- 6 January 2020